Impurity separator HSTA-1500

For separating foreign bodies from dewatered sludge

In practice, foreign bodies in dewatered sludge are a common cause of costly plant downtime in downstream recycling processes and necessitate inconvenient repair processes. The use of upstream impurity separators significantly increases the operational safety of the entire plant.

Impurity separator HSTA-1500, for separating foreign bodies from dewatered sludge

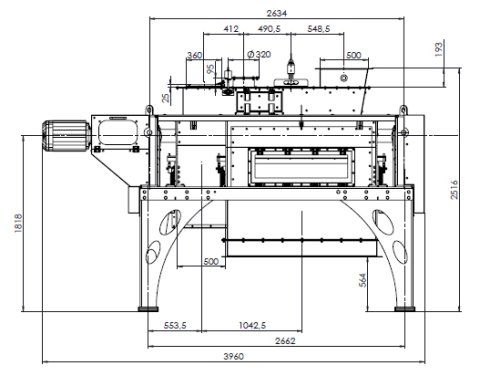

Principal dimensions

How does the HUNING impurity separator work?

Dewatered effluent sludge is fed onto two rollers working in opposing directions. Sludge and solids with a particle size that is smaller than the roller gap can pass through the (adjustable) gap of the separator. Larger solids are guided via a spiral-shaped groove on one of the two rollers towards the impurity ejector, where they are ejected. The impurity ejector is equipped with a pendular flap to prevent the undesired discharge of sludge.

Impurities that cannot be conveyed by means of the grooved roller pass through the roller gap, causing a deflection in the roller. This is detected and the separator is switched off. Adjustable sludge strippers prevent sludge from becoming stuck to the rollers.

The entire separation system is encased in a sludge-tight housing. Shaft openings are equipped with suitable sealing equipment. Impurities are separated out into a trough provided by the client or into an optional collecting container via a slide attached to the side of the system. The sludge, which is now free of impurities, passes through a discharge chute beneath the separator for onward transportation.

Technical details:

- Manufacturer: Huning Anlagenbau GmbH & Co. KG

- Type: HSTA-1500

- Throughput: up to approx. 20 m³/h

- Minimum gap: 5 mm

- Material used for rollers: Stainless steel 1.4301 or similar

- Material used for housing: Stainless steel 1.4301 or similar

- Adjustment range: approx. 5 - 20 mm

- Roller groove:

- Width: 40 mm

- Depth: 10 mm

- Gradient: 80 mm

- Roller diameter: approx. 320 mm

- Speed of rollers: approx. 300 rpm

- Outlet opening for foreign bodies: approx. 220 x 500 mm

- Drive output: 2 x approx. 11 kW

An air vent and the sensor system required for the separator to function correctly are included in the scope of supply of the machine.

An adequate number of inspection openings can be found at easily accessible positions for the purposes of swift and straightforward maintenance work. Lubrication points are provided in the form of a manual central lubrication system at an easily accessible position. The machine is mounted on a hot-dip galvanised substructure that meets the structural requirements. There is the option of ordering a self-sufficient compressed air supply for operating the bellows cylinders.