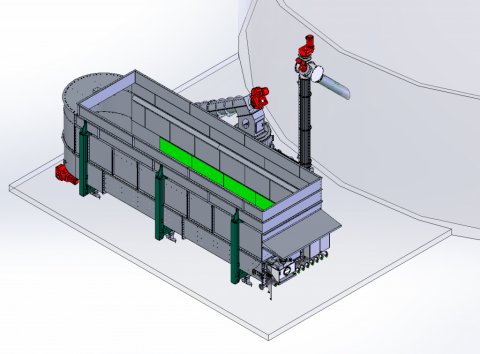

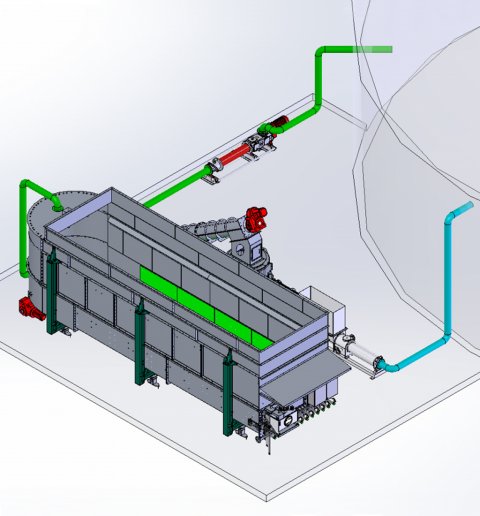

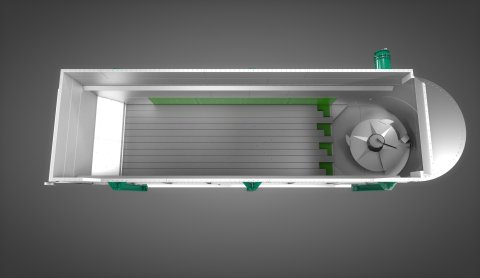

SFCE – Speed conveying floor

When it comes to light biomass with a low bulk density, such as the transport of cattle, turkey or horse manure with a high proportion of straw or materials from the recycling industry such as shredded film or similar materials.

Surfaces in contact with substrate made

of stainless steel or with plastic cladding

Feeding into processing zone

More facts

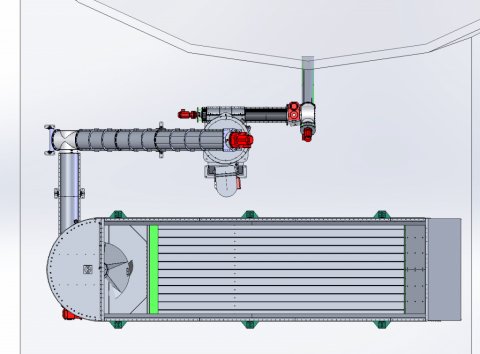

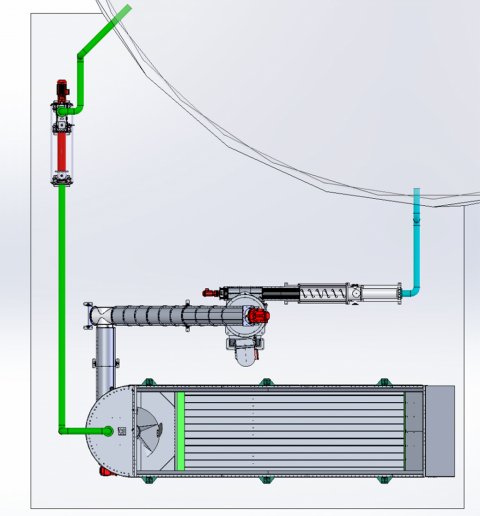

Hydraulically driven push bars are arranged in the bottom of the dosing device and feed the substrates to a processing

zone. The substrates are broken up by a mixing star or, alternatively, by rollers equipped with tools, and discharged via a

spiral conveyor. Alternatively, the dosing device can be equipped with a weighing device.

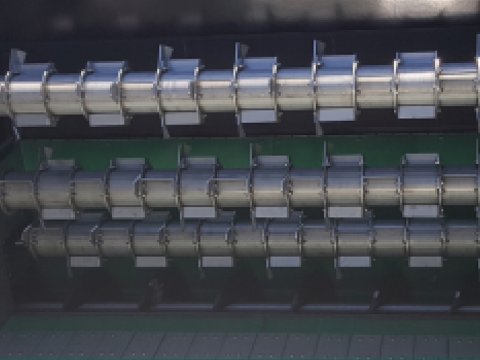

Resolution via mixed star

Resolution via rollers

Conveyance with spiral conveyors

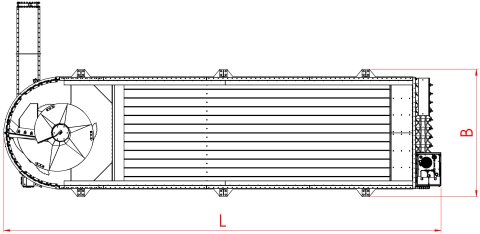

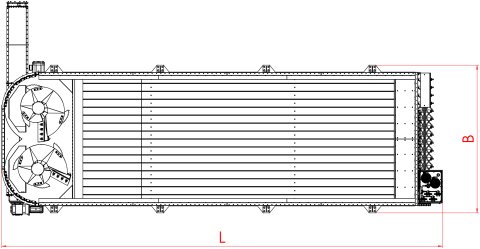

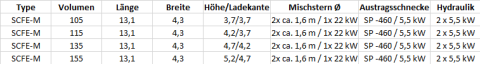

Main dimensions of the SFCE-M series

SCFE: Solids dosing system with one mixing star

SCFE: Solids dosing system with two mixing stars

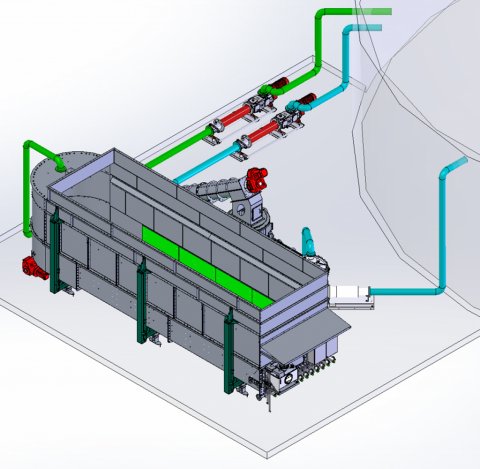

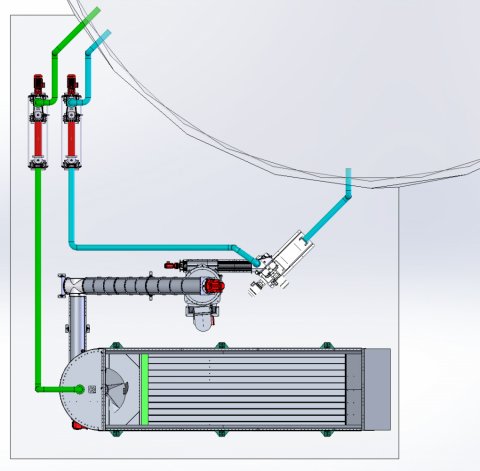

The SCFE complements the familiar model ranges of HUNING solids dosing devices and can therefore also be modularly

combined with all conveying and shredding systems in our range. Further conveying can take place via spiral conveyors,

pumps or other conveying technology. In combination with our shredding systems, especially our impact shredders or opti-

mised hammer mills, we are thus able to realise highly efficient processing systems for a wide range of biomasses from a

single source.